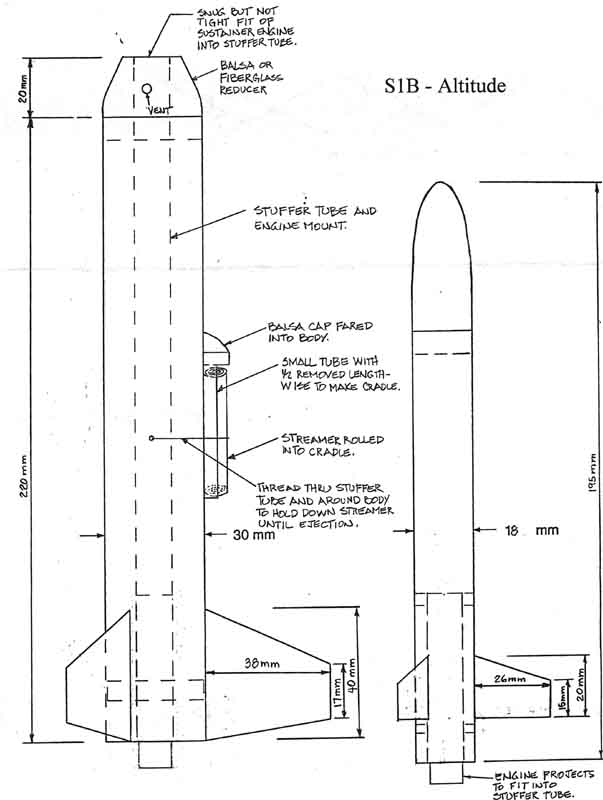

S1B Altitude Models

These models are somewhat different then your standard two stage

altitude model. The rules governing model diameters and length do not

allow direct staging of the upper stage from the lower stage in a

manner that is typical. Since the model must have a minimum diameter

of 30mm for at least 50% of its total length (which is a minimum of

350mm) the typical configuration is a lower stage of 30mm for a

minimum of 175mm topped by a reducer on top of which sits the second

stage (sustainer). This sustainer must conform to the 18mm body

diameter requirement. Refer to the FAI rules and Circular Number 3

which clarifies the 18mm requirement.

A typical model plan appears below:

The construction of these models is typically done with a fiberglass

and epoxy layup on a set of mandrels. Refer to the article on the

making of fiberglass tubes for construction techniques.

Some tips on making these models competitive are:

- Make the lower stage as light as possible. You don't want to burn

up potential altitude carrying a heavy first stage off the pad. - Use an altitude prediction program to determine the optimum weight

for the sustainer given the Cd of the sustainer and engine type you

are using. Try to build a sustainer that will have this weight when

fully prepped and ready to fly. - Build your sustainer strong enough to survive the rigors of ejecting

the tracking powder. (If it is too light the ejection charge will

blow out the side of the tube before the tracking powder can all get

out.) This usually means using more than two wraps of fiberglass. The

correct amount can only be determined by some experimentation.

Somewhere between two and six wraps is a good range to start. - Really work on getting a slick finish on the sustainer body and nose

cone. - Make sure that the nose cone has a perfect fit to the body tube.