S3A Parachute Duration Models

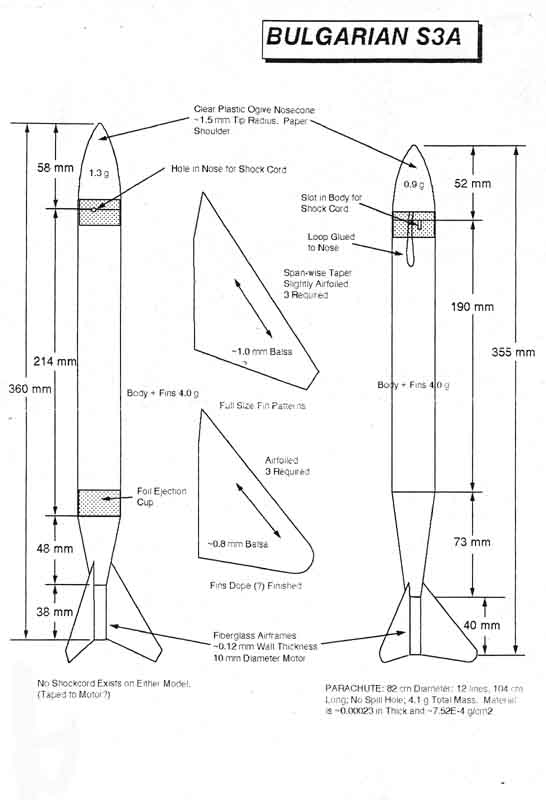

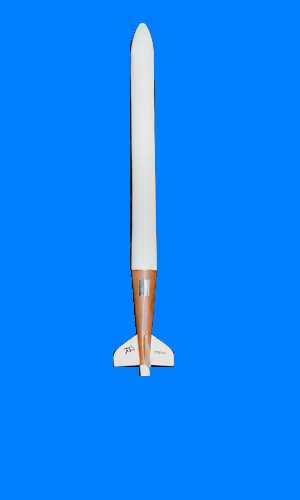

Entries for this event ordinarily have a mass of around 4 to 5 grams (model mass less parachute and motor mass)- very light considering they resemble the size and shape of an Estes Mini Bertha. Models must be a minimum of 350 mm in length with at least 50% of the length being 30mm in diameter. Because of the length and diameter restrictions, models for this event are composed typically of a straight 30mm diameter section which houses the recovery system and a boattailed section that reduces down to the motor diameter. See photo of the red rocket.

Most airframes are constructed using tissue and fiberglass and some have used paper or vellum. Parachutes are made from colored plastic or mylar and are 36" to 42" in diameter with 12 to 16 shroud lines. The nose cones are typically vacuum-formed plastic with a foam core shoulder. The fins are made out of either sheet fiberglass or thin balsa wood that is sometimes reinforced with tissue or fiberglass.

Building Techniques

A real popular method of creating lightweight airframes is via the use of tissue, fiberglass and epoxy resin. A mold is machined first out of aluminum and most machine shops will make them for under $100. Some sort of release agent is sprayed or applied to the mold and allowed to dry. Next, either the tissue or fiberglass is laid on top. Some wet the tissue or fiberglass out with epoxy before placing it on the mold- a wet lay-up. Others prefer to put a fine coat of epoxy on the mold and then lay the tissue or fiberglass on top- a dry lay-up. Whether or not the tissue is laid underneath or on top of the fiberglass is one's own preference, however, it should be employed so an airtight tube is created. Next, the tube is allowed to cure and then about 6 hours later (typical cure time), the mold is placed into an oven to activate the release agent. The tube at this time is slid off the mold and trimmed and/or sanded to meet the dimensional requirements.

Another favorite method used to create airframes is via white vellum drafting paper. Each section of the model is made by taping or gluing sheet vellum together to produce a cylinder or conical section. The sections are then connected using some sort of internal coupler. These tubes are easily made in a few minutes and can be made to be very light. Also, airframes made of vellum can easily be repaired since each section can be made to be removable. Some have used, with great success, both vellum and fiberglass construction to create a composite airframe. See the photo of the white and orange rocket.

The following drawing will give you the essential dimensions you will need to construct a S3A model. It is a a redrawn Bulgarian model.